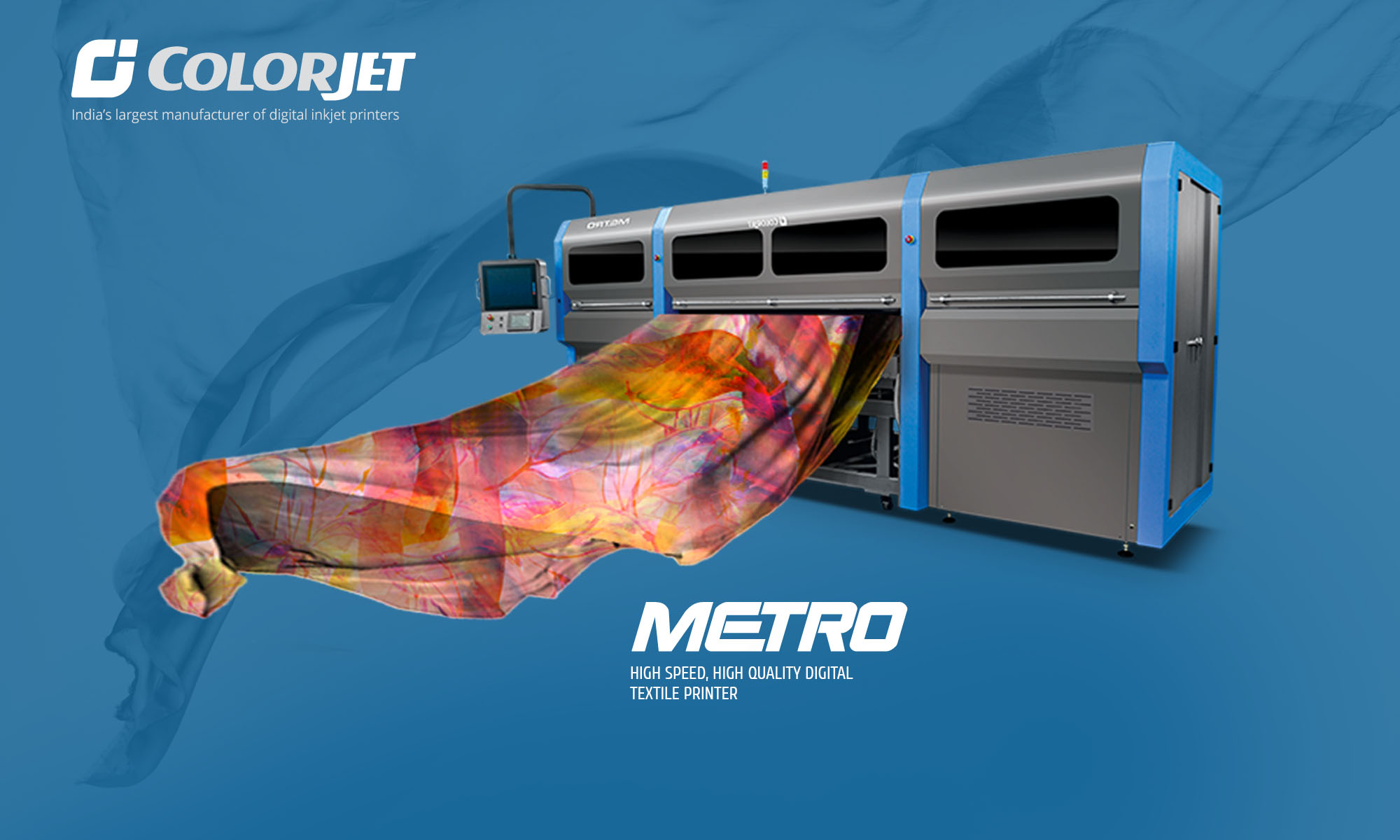

METRO - HIGH SPEED TEXTILE PRINTER IN BANGLADESH

METRO is a truly advanced industrial grade 1.8 meters wide digital fabric printing machine in bangladesh, which fantastically incorporates the latest technology and efficient engineering to meet the ever-growing demands of the textile business. As a digital textile printing consultant, ColorJet offers this high-speed fabric printing machine that is compatible to work with all types of inks like reactive, acid, disperse, and pigment. This industrial textile printer weaves magic on a variety of fabrics, ranging from 0.1 mm to 30 mm including cotton, polyester, silk, viscose, wool, nylon, acetate, or any other blended fabric. This high-speed digital textile printing machine from Indian textile printing leaders, ColorJet provides comprehensive textile printing solutions.

Why We Recommend

The advantages of the Metro include:

- Print System with 4/8/16/32 Industrial grade Jetting Assemblies for long Service Life

- Adhesive Belt Cleaning System : equipped with water jets and brush roller to wash excess ink and lint.

- Fabric Feed and Take-up System : Independent Fabric feed module with spreader roll to help remove wrinkles if any

- Infrared Dryer : Independent ink dryer module using power efficient radiation for minimal dissipation of heat to surroundings.

- RIP Software : Machines comes preloaded with Colorjet edition of the RIP Software with advanced Color Management engine and color processing tools.

- Ink System : Advanced degassing and de-bubbling avoids head blockage during high speed printing.

Features & Benefits

The brilliance that is METRO is built on a rigid structure to support 6, 16 & 32 head combination for long service life and deliver high-quality prints with speeds reaching upwards of 362 sq. meters per hour. The independent fabric feed module comes with a spreader roll to help remove wrinkles if any. This high-speed digital textile printing machine in bangladesh has a dancing roll and a guide roll to feed fabric with even tension.

Applications

Specifications

| Metro | |||||||

|---|---|---|---|---|---|---|---|

CONFIGURATION |

H8803 |

H8806

|

H8166 |

H8329 |

|||

| Printing Technology | Drop-on-demand, Piezo Electric Inkjet |

||||||

| No. of Print Heads | 8 KY |

8 KY |

16 KY |

32 KM |

|||

| Print Heads | Type | Industrial Grade Jetting Assemblies |

|||||

| Resolution | Upto 2400 DPI |

Upto 1440 DPI |

|||||

| Height Adjustment | upto 30mm |

||||||

| CleaningMethod | Pressure Purge and Wiping |

||||||

| Wetting Control | Piezoelectric Actuations |

||||||

| Inks | Types | Reactive/Disperse/Pigment/Acid |

|||||

| No of colors | 8 |

8 |

8 |

8 |

|||

| Supply | 10 Ltr, Bulk ink Supply System with inline degassing |

||||||

| Fabric | Types | Cotton,Viscose,Polyester,Polyamide,Silk,Wool |

|||||

| Max.Thickness | Upto 10mm |

||||||

| Max.Width | 1800 mm |

||||||

| Roll Width | 400mm |

||||||

| Fabric Drying System | Infrared Heaters |

||||||

| Operating Interface | Touch screen |

||||||

| Printing Interface | USB 3.1 |

||||||

| RIP Software Supported | ErgoSoft / NeoStampa (Colorjet Editions) |

||||||

| File Format | JPEG, TIFF, BMP/PDF (RGB, CMYK) |

||||||

| Power Supply | 220 V, 80 A Single/Three phase load distribution, 50Hz, |

||||||

| Operating Conditions | Temperature 18 to 28 C, Humidity: 35-80% RH ( Non-Condensing) |

||||||

| Printer Dimension / Net Weight | 5300 mm x 1840 mm x 2450 mm (LxWxH) / 4300 Kg. Approx. |

||||||

| Dryer Dimension / Net Weight | 2560 mm x 1500 mm x 1350 mm (LxWxH) / 500 Kg. Approx. |

||||||

| Feeder Dimension / Net Weight | 2350 mm x 800 mm x 1210 mm (LxWxH) / 617 Kg. Approx. |

||||||

| Speed In Sq. Meter/Hrs) | Print DPI |

Passes |

H8803 |

H8806

|

H8166 |

H8329 |

|

| Mode 1 |

|

1 |

256 |

- |

- |

- |

|

| Mode 2 |

|

2 |

195 |

- |

- |

- |

|

| Mode 3 | 600 x 900 |

3 |

139 |

- |

- |

- |

|

| Mode 4 | 600 x 1200 |

4 |

109 |

- |

- |

- |

|

| Mode 5 | 600 x 600 |

1 |

- |

210 |

362 |

- |

|

| Mode 6 | 600 x 1200 |

2 |

- |

123 |

187 |

- |

|

| Mode 7 | 600 x 1800 |

3 |

- |

88 |

151 |

- |

|

| Mode 8 | 600 x 2400 |

4 |

- |

68 |

121 |

- |

|

| Mode 9 | 540 x 720 |

2 |

- |

- |

- |

269 |

|

| Mode 10 | 540 x 1080 |

3 |

- |

- |

- |

194 |

|

| Mode 11 | 540 x 1440 |

4 |

- |

- |

- |

148 |

|